Generic cleaning plans fail because even “similar” facilities have dramatically different usage, wear patterns, and compliance requirements. Two office buildings or two charter schools need fundamentally different approaches – proving custom plans are essential, not optional.

This article will show you how to assess your facility’s needs, establish custom cleaning schedules, build the right team structure, and optimize for quality, efficiency, and cost.

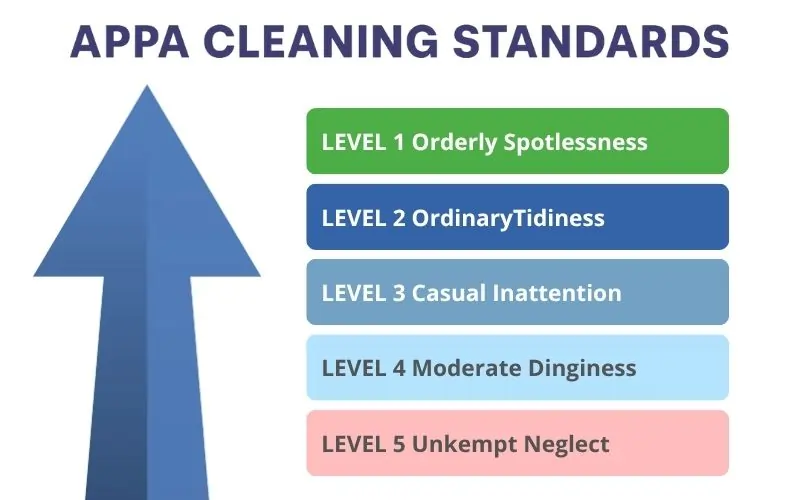

Custom cleaning plans align resources with actual facility needs through systematic assessment. APPA standards provide a clear framework for defining expectations by area. Strong team structure and facility-specific SOPs ensure consistent execution. Dynamic adjustment maintains optimal performance as conditions change.

Questions to Ask About Your Current Cleaning:

- Does your cleaning plan account for your facility’s specific traffic patterns and wear areas?

- Are you meeting NYC compliance requirements with proper documentation?

- Do different areas receive appropriate attention levels, or does everything get the same service?

- Can you demonstrate quality through measurable standards like APPA levels?

- Are you wasting budget on over-serviced areas while high-priority zones suffer?

If you’re using a generic approach, quantify the hidden costs in quality failures, compliance risks, and budget waste.

Custom cleaning plans deliver measurable ROI through improved quality, operational efficiency, and regulatory compliance. Get a complimentary facility assessment to identify improvement opportunities for your NYC facility.

Contact us for a complimentary assessment →

Why Custom Plans Matter: Even “Similar” Facilities Are Different

Two office buildings in Manhattan. Both 100,000 square feet. Both corporate offices. A facility management company applies the same “standard office cleaning package” to both buildings. After six months, one facility manager is satisfied while the other is drowning in complaints and quality issues.

What happened?

Every facility is different – even within the same category. Different layouts, traffic patterns, surfaces, and compliance requirements demand different approaches. Generic “one-size-fits-all” cleaning creates quality inconsistencies, wasted resources, and compliance risks. Custom cleaning plans align resources with actual facility needs.

Two Corporate Offices, Completely Different Needs

Consider two office buildings in Manhattan, both 100,000 square feet of corporate space. On paper, they look identical. In reality, their cleaning needs couldn’t be more different.

Office Building Comparison

| Factor | Office Building 1Older Facility | Office Building 2Class A Building |

| Occupancy | 800 employees 8 people per 1,000 sq ft | 400 employees 4 people per 1,000 sq ft |

| Layout | Traditional cubicles, congested Multiple conference rooms 3 break rooms with full kitchens | Open floor plan, spacious Few enclosed meeting spaces 1 modern break area |

| Flooring | Carpet throughout (20+ years old) VCT in break rooms and restrooms | Polished concrete in main areas Wood floors in conference rooms Tile in break rooms/restrooms |

| High-Traffic Areas | All restrooms (constant use) Break room kitchens (3 locations) Main elevator lobby Conference rooms (daily bookings) | Executive restroom only Single break area Main entrance Conference rooms (sporadic use) |

| Surface Wear | Carpet shows heavy traffic lanes, Kitchen counters constantly used, door handles Light switches show wear | Concrete floors hide wear well Minimal kitchen use, open space reduces touch points |

| Cleaning Priorities | Daily carpet maintenance critical, Multiple kitchen deep cleans, Frequent restroom service (high usage) High-touch surface focus | Dust control on concreteWood floor preservation Minimal kitchen needs Aesthetic presentation focus |

Office Building 1’s congested layout with carpet flooring means daily vacuuming is critical – those traffic lanes will show neglect within 24 hours. The three break room kitchens need multiple daily services to handle the volume from 800 employees.

Meanwhile, Office Building 2’s concrete floors and minimal kitchen use mean those same daily services would waste resources.

Apply the same “standard office package” to both, and one facility manager gets exactly what they need while the other faces constant quality issues and budget waste.

Charter Schools: Two Schools, Different Demands

Now consider two charter schools in NYC, both subject to the same green cleaning compliance requirements. Both serve students, both need food-safe cafeterias, both have high foot traffic. Yet their cleaning plans must be completely different.

Charter School 1’s maple hardwood gym floor alone requires specialized expertise – improper cleaning products or techniques can damage the finish and cost $50,000+ to replace. The elementary grades generate dramatically more mess, spills, and bathroom accidents than high school students, requiring more frequent and thorough cleaning protocols. The three-story layout means stairwells become high-traffic chokepoints that need multiple daily services.

Charter School 2’s single floor with older students allows more efficient routing and less intensive protocols in many areas – yet both would receive the same “standard school cleaning” under a generic approach.

Beyond Offices and Schools: Specialized Facilities

The differences become even more pronounced with specialized facilities.

- A distribution warehouse in the Bronx prioritizes floor safety for forklift operations and OSHA compliance over aesthetic cleaning – concrete floors need different care than office carpet, and loading dock areas endure more wear in one shift than a corporate lobby sees in a week.

- Museums and tourist attractions in Manhattan balance high visitor volume with preservation concerns for artifacts and specialty materials, requiring cleaning methods that won’t damage irreplaceable exhibits.

- Healthcare facilities operate under the strictest protocols of all, where a charter school’s “clean” is a hospital’s “contaminated” – surgical suites require pathogen reduction verification that would be unnecessary overkill in administrative offices.

How to Assess Your Facility’s Cleaning and Maintenance Needs

Step 1: Map Your Facility by Function and Traffic

Start by documenting how your facility actually operates:

- Identify distinct zones: Public areas, back-of-house spaces, specialized rooms

- Document traffic patterns: When do people arrive? Which areas get the most use?

- Note surface types: Carpet, concrete, wood, tile, specialty materials

- Measure actual wear patterns: Don’t assume – observe where dirt and wear accumulate

Step 2: Identify Regulatory Requirements

NYC facilities face specific compliance requirements depending on facility type:

- Charter schools: NYC green cleaning laws require EPA Safer Choice products and specific protocols

- Food service areas: NYC Department of Health standards for cafeterias and kitchens

- Healthcare facilities: Infection control protocols and Joint Commission standards

- All facilities: OSHA safety requirements, building codes, waste management regulations

Step 3: Establish Priority Areas

Different facilities have different priorities. Here’s how to identify yours:

EXAMPLE: Priority Assessment by Facility Type

| Facility Type | Highest Priority | Medium Priority | Lower Priority |

| Office Building | Reception/lobby (first impression) Executive areas (business critical) Restrooms (health/comfort) | General office spaces Conference rooms Break rooms | Storage areas Mechanical rooms Parking structures |

| Charter School | Cafeteria (food safety) Classrooms (health focus) Restrooms (compliance + health) | Hallways Gymnasium Common areas | Administrative offices Storage areas |

Step 4: Determine Operational Constraints

Your cleaning schedule must work around your operations:

- Operating hours and access: When can cleaning happen without disrupting work?

- Occupant presence: Are students, employees, or patients present during cleaning?

- Seasonal variations: Do summer months allow deeper cleaning? Holiday schedules?

- Special events: Conferences, open houses, inspections that need extra attention?

Document Your Assessment

Create facility-specific documentation:

- Priority matrix showing which areas need what level of attention

- Compliance requirements checklist for your facility type

- List of specialized protocols needed (green cleaning, infection control, etc.)

- Budget allocation based on priorities

Documentation is necessary for improvement, and delivering consistent quality across multiple facilities, and for some facilities a compliance need.

Establishing Your Custom Cleaning Schedule

When creating your custom cleaning plan, it’s important to structure your schedule to include daily cleaning tasks, weekly tasks, and weekly cleaning tasks.

Assigning specific weekly cleaning tasks—such as dusting, vacuuming, and bathroom deep cleans—to certain days ensures that all areas of your home receive attention on a regular basis.

Incorporating daily cleaning tasks like sweeping, mopping, trash removal, and laundry into your routine helps maintain a consistently clean environment and prevents chores from piling up.

Scheduling weekly cleaning tasks can be especially effective for making sure no area is overlooked, while daily tasks like laundry keep your home running smoothly.

Creating Your Custom Schedule

Once you’ve assigned APPA levels, create your schedule:

Daily Tasks:

- High-priority areas maintaining

- Restrooms, entrances, high-traffic zones

- Kitchen and food service areas

- High-touch surfaces

Weekly Deep Cleaning:

- Detailed cleaning in medium-priority areas

- Specialty services like floor care in specific zones

- Window cleaning in public areas

Monthly Services:

- Floor stripping and waxing

- High-level dusting

- Window cleaning exterior

- Deep carpet extraction

Quarterly/Annual Projects:

- Complete floor restoration

- Seasonal deep cleaning (charter schools in summer)

- Specialty maintenance (gym floor refinishing)

- Compliance audits and documentation review

Schedule Coordination:

- Align cleaning times with facility operations

- Minimize disruption to students, employees, or patients

- Build in flexibility for special events or seasonal changes

Building Your Team, Training, and Performance Systems

Team Structure and Roles

A custom cleaning plan needs a team that understands your facility’s specific needs:

Cleaning Technicians:

- Execute daily protocols following facility-specific SOPs

- Document completion with photo verification

- Flag issues for immediate attention

Team Leads:

- Oversee shift operations and task completion

- Verify quality before leaving each area

- Provide real-time guidance to technicians

Site Supervisors:

- Manage facility-specific operations

- Conduct quality inspections against APPA standards

- Handle communication with facility manager and issue resolution

Quality Control Manager:

- Oversee multiple facilities for consistency

- Review performance data and identify trends

- Coordinate improvements across portfolio

Facility-Specific Staffing Considerations

Different NYC facilities require different expertise:

- Hospitals: Specialized infection control training, understanding of pathogen reduction protocols

- Charter Schools: Background checks, child safety awareness, green cleaning compliance.

- Warehouses: Safety training, equipment operation clearance, OSHA compliance knowledge

- Office Buildings: Professional appearance, discretion, after-hours security coordination

Why Facility-Specific SOPs Matter

Generic procedures don’t account for:

- Surface-specific methods: Maple hardwood requires different care than VCT, which differs from carpet, concrete, and tile

- Product selection: NYC charter schools must use EPA Safer Choice products; hospitals need EPA-registered disinfectants

- Equipment operation: Autoscrubbers for large warehouses vs. backpack vacuums for offices

- Compliance documentation: NYC green cleaning logs, infection control verification, OSHA safety records

Digital SOPs Provide Consistency

Technology-driven SOPs ensure quality regardless of who’s on shift and when new staff needs training:

- Real-time guidance prevents errors and inconsistency

- Photo documentation creates quality verification

- Automatic compliance audit trails for NYC regulations

- Updates distribute instantly when protocols change

Training Framework

Initial Certification:

- Facility-specific protocols and expectations

- Surface and product training for your materials

- NYC compliance requirements (green cleaning, safety, etc.)

- Emergency procedures and communication protocols

Ongoing Development:

- Skill development as facility needs evolve

- Compliance updates when NYC regulations change

- Cross-training for operational flexibility

Performance Measurement and Quality Control

Key Performance Indicators (KPIs):

- Quality scores by area with APPA level adherence tracking

- Task completion verification through digital systems

- Response time for urgent issues

- Compliance documentation completeness for NYC audits

- Occupant satisfaction metrics from surveys

Performance Review Systems:

- Daily: Quality inspections against defined standards

- Weekly: Performance trending and issue identification

- Monthly: Facility reviews with stakeholders

- Quarterly: Improvement planning sessions

Continuous Improvement Process:

- Issue identification with root cause analysis

- Protocol adjustments based on performance data

- Seasonal optimization (summer deep cleaning for schools, holiday prep for offices)

- Budget efficiency tracking

Adjusting Plans to Achieve Quality, Efficiency, and Cost Goals

Why Custom Plans Must Be Dynamic

Quality Optimization:

- Performance data shows which areas aren’t meeting standards

- Adjust frequencies or methods where needed

- Reallocate resources from over-serviced areas to high-priority zones

- Enhance protocols based on measurable results

Efficiency Optimization:

- Eliminate redundant tasks identified through tracking

- Optimize team routes and schedules based on actual workflow

- Right-size staffing using workload data

- Technology integration for better coordination

Cost Optimization:

- Identify over-serviced areas consuming unnecessary budget

- Adjust frequencies based on actual usage and wear patterns

- Product optimization for better results per dollar

- Preventive maintenance reduces expensive emergency interventions

Advantage Cleaning Help Facility Professional Achieve Their Quality & Efficiency Goals, Without Management Burden

Custom cleaning plans deliver superior results, but many NYC facility directors worry about the time investment to create, implement, and manage them.

Advantage Cleaning engineers custom cleaning plans that deliver predictable results without requiring daily oversight from facility management. Our integrated team structure—Quality Control Manager, Site Supervisor, Team Lead, and trained technicians—operates with technology-driven systems that provide:

- Automatic compliance documentation: Audit-ready files for NYC green cleaning requirements, OSHA standards, and facility-specific regulations available on demand

- Real-time quality verification: Photo documentation and digital task tracking show completion and quality

- Proactive issue resolution: Problems flagged and resolved before they impact operations or occupant satisfaction

- Clear performance visibility: KPIs without manual tracking or spreadsheet management

The result: Facility directors experience 70% reduction in cleaning oversight time while achieving higher quality standards and complete compliance readiness.

Learn more about our Quality Control System →

A higher grade of Quality in Commercial Cleaning

Commercial Cleaning in CONNECTICUT

FAQ – Custom Cleaning Plans for NYC Facilities

Relevant articles

General Cleaning vs Deep Cleaning – Important Differences

The Guide to APPA Cleaning Standards for Educational, Healthcare, and Institutional Facilities in NYC

Introduction Facility Managers and Chief Operating Officers (COOs) overseeing educational institutions, healthcare facilities, and public…

Commercial Toilet Cleaning: Public Health, Compliance & Best Practices for NYC and NJ Facilities

In any commercial facility, from high-rise offices to industrial plants and healthcare clinics, restrooms are…